SoW : Sensor on Wafer

Capella Series

[ T / C / P ]

Our Sensor Wafer (Capella Series) is used to verify the process conditions in the etching process, which is the core of the semiconductor process. We are designed to be applicable to various test conditions from high temperature to cryogenic temperature, and plasma conditions, are used as essential process equipment for etching equipment by providing accurate measurements for a stable test environment and actual production.

Product necessity

With the development of semiconductor process technology, the precision of line width is getting more precise. In addition, the performance of etching equipment is also being advanced, and technologies such as high temperature, cryogenic temperature, various plasma environments, and EVU application are changing. In order to secure the maintenance and process stability of these equipment, the necessity of sensor wafer is emerging as an essential equipment, and in addition, technological development and cooperative development companies are required. We are developing sensor wafer that can be applied to various conditions such as high temperature, cryogenic temperature, plasma, and EUV environment, and supply products through partnerships between equipment manufacturers and semiconductor manufacturers.

-

01

- Check chamber status diagnosis using SoW

- Equipment maintenance optimization

-

02

- Increase semiconductor output

- Strengthen price competitiveness

Area of using SoW products

- 01 Semiconductor process miniaturization and precision

- 02 Process reproducibility

- 03 Real-time process mechanism analysis Technology

- 01 Process equipment condition diagnosis technology

- 02 Increased yield

Capella Series - T/C/P

Product Specification

Our sensor wafer (Capella Series) supplies a line-up for measuring the temperature and plasma in the ESC and Bath of etching equipment. Customers can choose according to the high temperature /extreme temperature and plasma conditions, and EUV measurement line-up and plasma density measurement line-up will be added in the future, and the line-up is expanding to various measurement environments. In addition, station and coupe can be selected as components suitable for the measurement environment, and an analysis program for analysis of measured values is also organized. It is also possible to develop and collaborate to meet the customer's acceptance and needs.

Custom diagnostic system

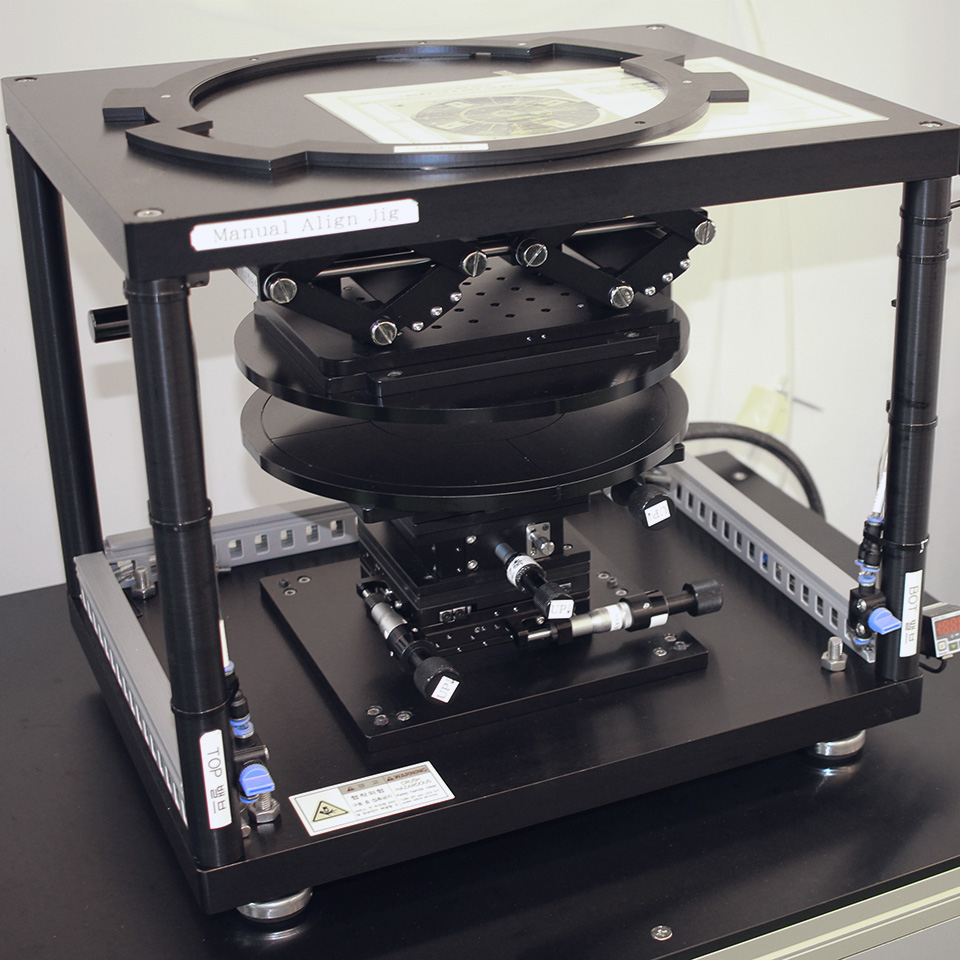

Manufacturing and development capabilities

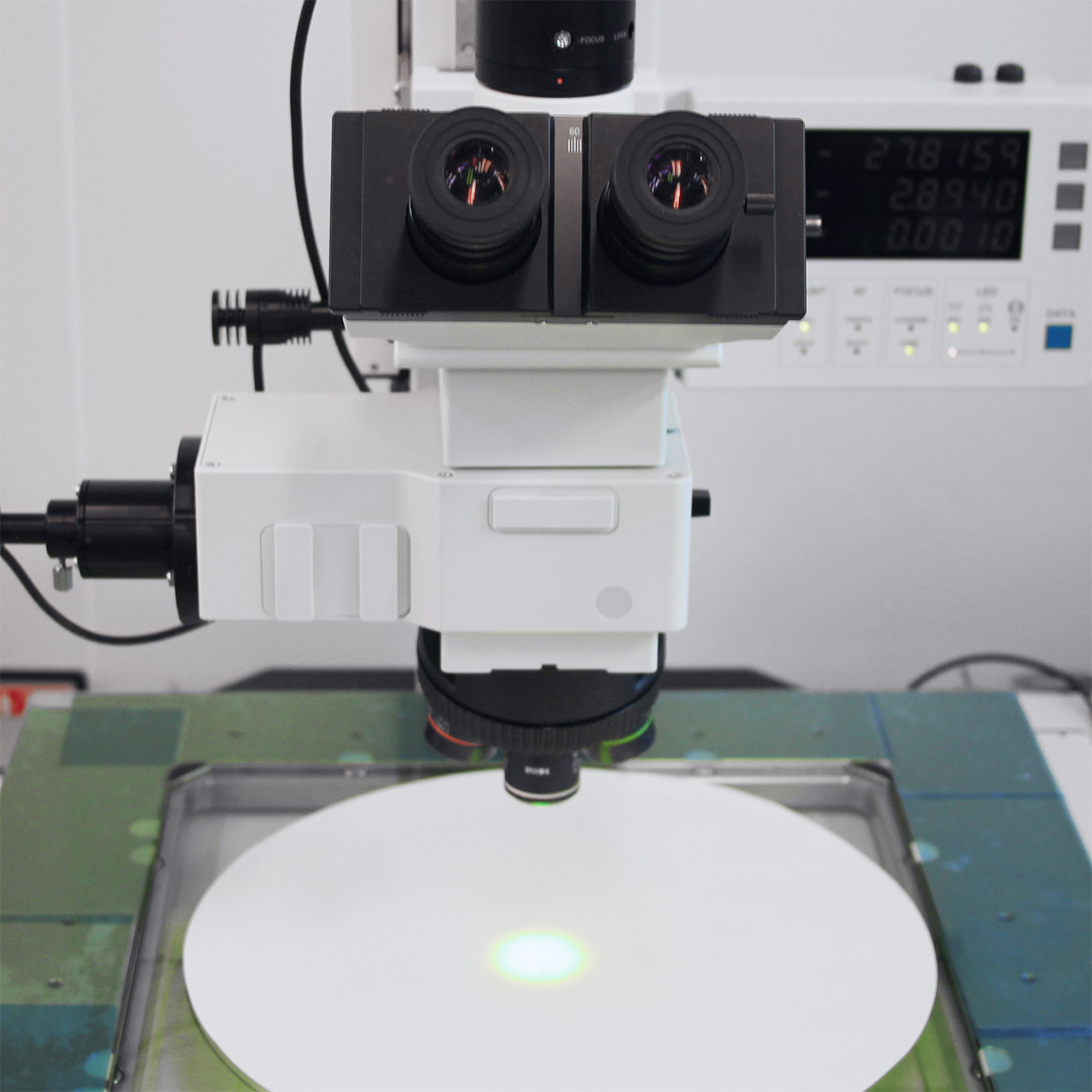

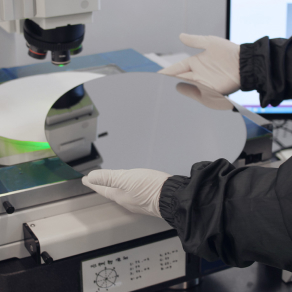

Possessing dedicated Fab facilities, equipment & analysis systems for the development and production of 300mm wafer type sensors.

- Development and know-how for wafer-type sensors

- Holds numerous patents essential for the development of various wafer-type sensors

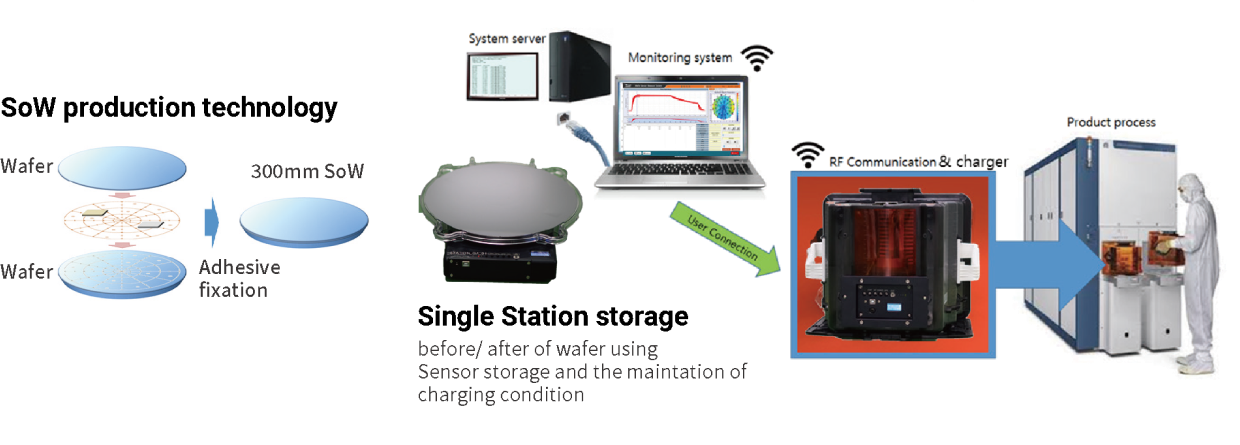

SoW product

Product main composition

-

SoW

Wafer type sensor Ass’y

- Between top and bottom there is a built-in sensor /circuit- sensor, driving element, memory, battery, wireless transmission, reception and charging antena, etc.

-

Single Station

Cradle dedicated to SoW utilization

- Wireless data transmission and reception and wireless charging function

-

Foup

Cassette for SoW utilization in process equipment

- Wireless data transmission and reception and wireless charging function

-

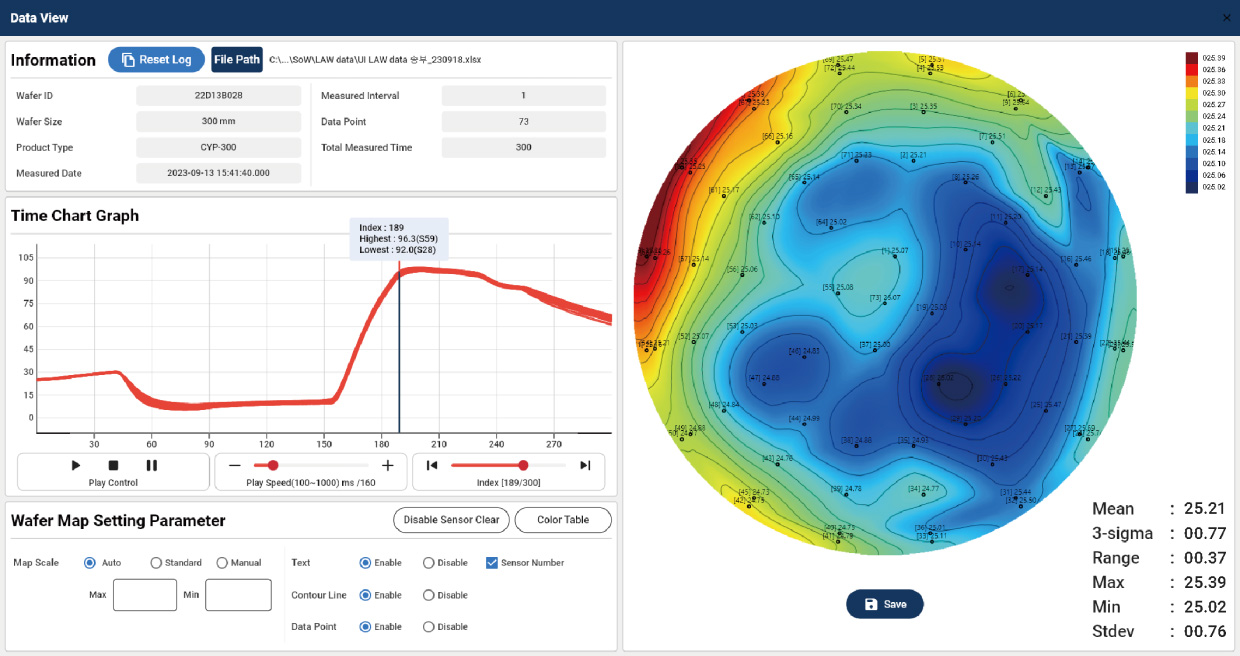

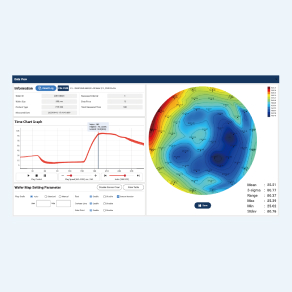

UI

Dedicated program for utilizing SoW

- SoW status monitoring, various settings of parameter values, Sending/receiving measurement data and implementing charts

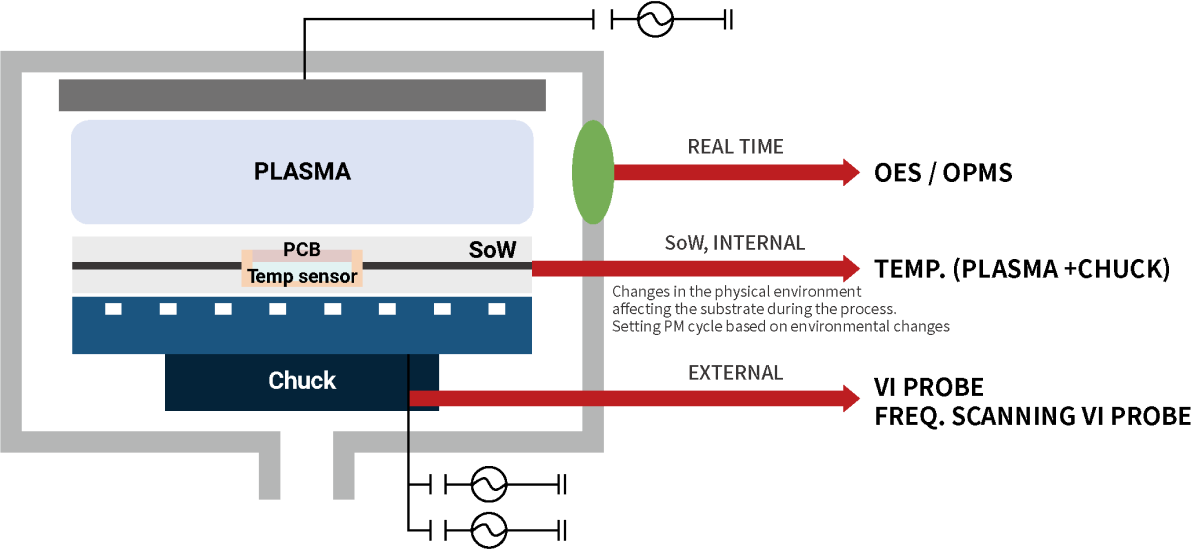

SoW usage and evaluation diagram

Reliability performance test -

Etcher system

- System : ICP-RIE etcher

- RF Power : 4.5kW (Source) / 4 kW (Bias)

- Plasma “ON” time : 180 sec

In order to secure stable measurement results and ensure uniformity, we ship products after measurement and verification in various environments. We have facilities and process equipment for related verification.